Industrial Door Repairs

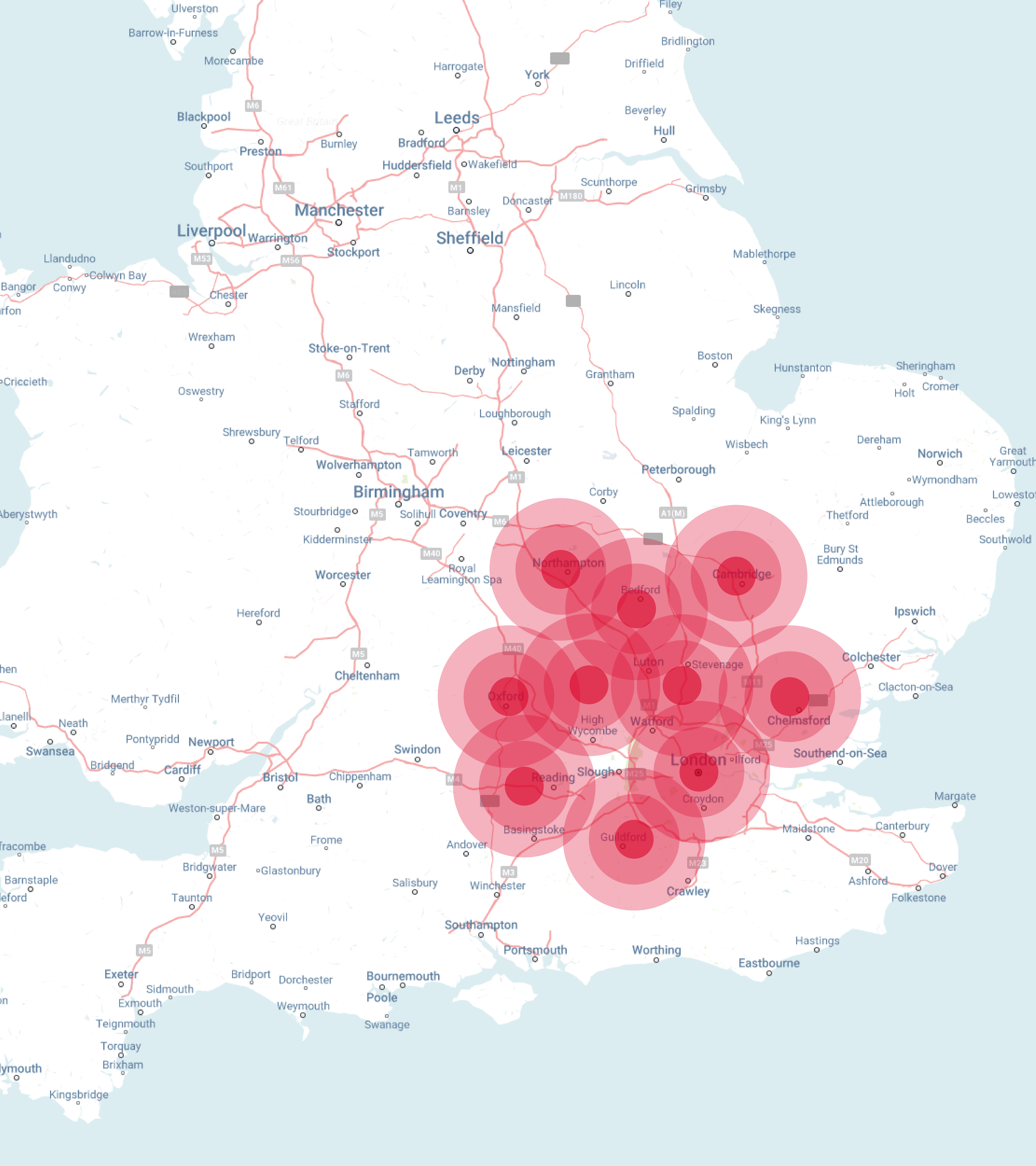

At RID Repairs, we know how key industrial doors are in the smooth operation of your business. That's why we provide fast, efficient and reliable repairs across Bedfordshire, Hertfordshire, Buckinghamshire, Cambridgeshire and London, together with surrounding areas. Our team of skilled engineers is always ready to respond to your broken door, be it an emergency call-out or a non-emergency call out, we ensure your doors are operational as quickly as possible.

- Fast Response Times - Quick response to minimize downtime and disruption

- 24/7 Emergency Call-Outs - Available around the clock to handle urgent repair needs

- Skilled Engineers – Trained professionals with experience in industrial door repairs

- High First-Time Fix Rate – Equipped with as many parts as possible to try to resolve issues on the first visit

Rapid response request

If you need an urgent call-out then submit your name and phone number and we'll call you back immediately to run through costs and estimated arrival time.

Here’s why you should choose RID

Highly Experienced Engineers

Skilled professionals with extensive industry knowledge.

Thorough Maintenance

Comprehensive checks to extend the life of your door.

Quality Replacement Parts

We use high-quality spare parts and secure door models.

Protect your business with RID, expert industrial door repairs and maintenance. Contact us today to schedule a service or learn more about how we can help safeguard your premises.

Fast Response and Emergency Call-Outs

In the commercial sector, downtime can mean financial losses and security issues. We work to rapid response times to reduce disruption to your company. Our emergency call-out repair service is available 24 hours 7 days a week, ensuring that no matter the time of day or night, you can count on us to address your door issues promptly.

Skilled Engineers

Our team is made up of experienced engineers who specialise in industrial door repairs. Their expertise spans a wide range of door types, including roller shutters, sectional doors, high-speed doors and fire doors. Each engineer is trained to diagnose and fix issues swiftly, ensuring minimal downtime and aiming to fix on the first visit.

View other areas of our website

First-Time Fixes

We get that cost is a big issue and pride ourselves on our high first-time fix rate. Our engineers come equipped with a comprehensive range of parts, helping them resolve most issues on the first visit. This saves you time but also reduces the overall cost of a repair.

Coverage

While we mainly provide call-outs to Bedfordshire, Hertfordshire, Buckinghamshire, and Cambridgeshire, our network extends across the south of England. This helps us give a consistent and reliable service no matter where your operations are located.

FAQs

What types of industrial doors do you repair?

RID Repairs provides comprehensive industrial door repair services across multiple door systems commonly found throughout commercial and industrial premises. Roller shutter repairs constitute a substantial portion of our workload, as these robust security doors are extensively utilised across warehouses, retail establishments, and manufacturing facilities throughout Bedfordshire, Hertfordshire, and neighbouring counties. Sectional overhead door repairs require specialised knowledge owing to their complex spring and track mechanisms. These doors are particularly favoured at loading bays and facilities requiring maximum opening clearance. High-speed door repairs present distinctive challenges given their rapid operation cycles and sophisticated control systems. Fire door repairs demand strict adherence to safety regulations and compliance standards. Our engineers maintain current knowledge of evolving door technologies whilst stocking commonly required replacement components. This approach enables us to achieve high first-time repair success rates, minimising business disruption and reducing overall repair costs for our commercial clients.

How quickly can you respond to emergency door repair callouts?

Emergency industrial door repair response times directly impact business security and operational continuity. RID Repairs has structured our emergency callout service to minimise downtime through strategic engineer deployment and comprehensive parts inventory management. During standard business hours across our primary service areas of Bedfordshire, Hertfordshire, Buckinghamshire, and Cambridgeshire, typical response times range from 90 minutes to 3 hours depending upon location and current service commitments. Out-of-hours emergency door repairs operate under our 24/7 callout service with engineers on standby rotation. Weekend and evening callouts naturally incur premium pricing owing to the specialised nature of emergency response services. Geographic coverage optimisation means our engineers are strategically positioned throughout our service territory. Each service vehicle carries diagnostic equipment and frequently required replacement parts, maximising the probability of same-visit repair completion. When you contact our emergency repair service, we provide realistic arrival time estimates and maintain communication throughout the response process.

Do you provide preventive maintenance services for industrial doors?

Preventive maintenance programmes represent one of the most cost-effective approaches to industrial door management. RID Repairs offers structured maintenance contracts designed to prevent unexpected failures whilst ensuring compliance with safety regulations and manufacturer warranty requirements. Our maintenance methodology involves systematic inspection of mechanical components including spring assemblies, cable systems, track alignment, and bearing assemblies. Wear pattern analysis helps predict component replacement timing, allowing scheduled maintenance rather than emergency repairs. Electrical system maintenance covers motor performance evaluation, control panel diagnostics, and safety system functionality testing. Photo-electric sensors, pressure-sensitive safety edges, and emergency stop systems require regular calibration to maintain optimal performance. Maintenance frequency recommendations vary based upon usage patterns and environmental conditions. High-traffic installations benefit from quarterly inspections, whilst moderate-use doors typically require bi-annual service visits. Regular maintenance extends equipment lifespan, maintains energy efficiency in climate-controlled facilities, and reduces total ownership costs. Learn more about our maintenance services.

What should I do if my industrial door gets stuck or won't open?

Industrial door malfunctions require careful assessment to prevent injury and avoid exacerbating existing problems. When your door system fails to operate normally, following proper safety protocols protects personnel whilst preserving repair options. Initial troubleshooting should focus on obvious causes without attempting mechanical intervention. For motorised systems, verify power supply integrity and check for activated emergency stops or safety interlocks. Visual inspection from a safe distance may reveal obvious obstructions in door tracks or damaged components. However, avoid physical contact with springs, cables, or counterweight systems as these components operate under extreme tension and pose serious injury risks. If the door is partially open, maintain a safe perimeter around the opening. Never attempt to pass through compromised openings or position vehicles beneath unstable door systems. Documentation through photographs assists our repair technicians in preparation and parts selection. When contacting RID Repairs for emergency service, detailed description of symptoms helps our dispatch team provide appropriate guidance. Contact us immediately for professional assistance.

How do you determine the cost of industrial door repairs?

Industrial door repair pricing reflects multiple variables that influence both labour requirements and material costs. RID Repairs employs transparent pricing methodology to ensure customers understand cost components and can make informed decisions about repair investments. Diagnostic assessment forms the foundation of accurate repair pricing. Complex mechanical failures require systematic troubleshooting to identify root causes and determine appropriate repair strategies. Simple adjustments or minor component replacements naturally cost less than major system overhauls or complete motor replacements. Replacement parts pricing varies significantly based upon manufacturer specifications, component availability, and system age. Our extensive parts inventory helps control costs by reducing expedited delivery charges and multiple service visits. Labour costs reflect both time requirements and technical complexity. Emergency service calls include premium charges reflecting out-of-hours availability and immediate response capabilities. Weekend and bank holiday repairs command higher rates owing to the specialised nature of emergency technical services. Comprehensive cost estimates are provided before work commences, with clear explanations of recommended repairs and associated costs. Get a quote for your repair requirements.

Are your engineers qualified to work on all brands of industrial doors?

RID Repairs maintains a team of experienced engineers with extensive cross-manufacturer expertise developed through years of field experience and ongoing professional development. Our technicians regularly encounter diverse door systems and have developed comprehensive knowledge of various manufacturer specifications and repair requirements. Technical training encompasses both formal manufacturer programmes and hands-on experience with popular brands including Hörmann, Carteck, Novoferm, and numerous other industrial door manufacturers. This broad exposure enables our engineers to understand design principles and common failure patterns across different product lines. Diagnostic capabilities extend beyond brand-specific knowledge to fundamental mechanical and electrical principles. Springs, motors, control systems, and safety devices operate on similar principles regardless of manufacturer branding. Parts sourcing relationships with multiple suppliers ensure access to replacement components for most door systems. Compatible parts availability often provides cost-effective alternatives to original manufacturer components whilst maintaining performance standards. Older or discontinued door systems occasionally present unique challenges when manufacturer support is limited. Our engineers' broad experience often enables creative solutions utilising available components or system modifications that restore functionality whilst maintaining safety standards. Learn more about our team.

What types of industrial doors do you repair?

RID Repairs provides comprehensive industrial door repair services across multiple door systems commonly found throughout commercial and industrial premises. Roller shutter repairs constitute a substantial portion of our workload, as these robust security doors are extensively utilised across warehouses, retail establishments, and manufacturing facilities throughout Bedfordshire, Hertfordshire, and neighbouring counties. Sectional overhead door repairs require specialised knowledge owing to their complex spring and track mechanisms. These doors are particularly favoured at loading bays and facilities requiring maximum opening clearance. High-speed door repairs present distinctive challenges given their rapid operation cycles and sophisticated control systems. Fire door repairs demand strict adherence to safety regulations and compliance standards. Our engineers maintain current knowledge of evolving door technologies whilst stocking commonly required replacement components. This approach enables us to achieve high first-time repair success rates, minimising business disruption and reducing overall repair costs for our commercial clients.

How quickly can you respond to emergency door repair callouts?

Emergency industrial door repair response times directly impact business security and operational continuity. RID Repairs has structured our emergency callout service to minimise downtime through strategic engineer deployment and comprehensive parts inventory management. During standard business hours across our primary service areas of Bedfordshire, Hertfordshire, Buckinghamshire, and Cambridgeshire, typical response times range from 90 minutes to 3 hours depending upon location and current service commitments. Out-of-hours emergency door repairs operate under our 24/7 callout service with engineers on standby rotation. Weekend and evening callouts naturally incur premium pricing owing to the specialised nature of emergency response services. Geographic coverage optimisation means our engineers are strategically positioned throughout our service territory. Each service vehicle carries diagnostic equipment and frequently required replacement parts, maximising the probability of same-visit repair completion. When you contact our emergency repair service, we provide realistic arrival time estimates and maintain communication throughout the response process.

Do you provide preventive maintenance services for industrial doors?

Preventive maintenance programmes represent one of the most cost-effective approaches to industrial door management. RID Repairs offers structured maintenance contracts designed to prevent unexpected failures whilst ensuring compliance with safety regulations and manufacturer warranty requirements. Our maintenance methodology involves systematic inspection of mechanical components including spring assemblies, cable systems, track alignment, and bearing assemblies. Wear pattern analysis helps predict component replacement timing, allowing scheduled maintenance rather than emergency repairs. Electrical system maintenance covers motor performance evaluation, control panel diagnostics, and safety system functionality testing. Photo-electric sensors, pressure-sensitive safety edges, and emergency stop systems require regular calibration to maintain optimal performance. Maintenance frequency recommendations vary based upon usage patterns and environmental conditions. High-traffic installations benefit from quarterly inspections, whilst moderate-use doors typically require bi-annual service visits. Regular maintenance extends equipment lifespan, maintains energy efficiency in climate-controlled facilities, and reduces total ownership costs. Learn more about our maintenance services.

What should I do if my industrial door gets stuck or won't open?

Industrial door malfunctions require careful assessment to prevent injury and avoid exacerbating existing problems. When your door system fails to operate normally, following proper safety protocols protects personnel whilst preserving repair options. Initial troubleshooting should focus on obvious causes without attempting mechanical intervention. For motorised systems, verify power supply integrity and check for activated emergency stops or safety interlocks. Visual inspection from a safe distance may reveal obvious obstructions in door tracks or damaged components. However, avoid physical contact with springs, cables, or counterweight systems as these components operate under extreme tension and pose serious injury risks. If the door is partially open, maintain a safe perimeter around the opening. Never attempt to pass through compromised openings or position vehicles beneath unstable door systems. Documentation through photographs assists our repair technicians in preparation and parts selection. When contacting RID Repairs for emergency service, detailed description of symptoms helps our dispatch team provide appropriate guidance. Contact us immediately for professional assistance.

How do you determine the cost of industrial door repairs?

Industrial door repair pricing reflects multiple variables that influence both labour requirements and material costs. RID Repairs employs transparent pricing methodology to ensure customers understand cost components and can make informed decisions about repair investments. Diagnostic assessment forms the foundation of accurate repair pricing. Complex mechanical failures require systematic troubleshooting to identify root causes and determine appropriate repair strategies. Simple adjustments or minor component replacements naturally cost less than major system overhauls or complete motor replacements. Replacement parts pricing varies significantly based upon manufacturer specifications, component availability, and system age. Our extensive parts inventory helps control costs by reducing expedited delivery charges and multiple service visits. Labour costs reflect both time requirements and technical complexity. Emergency service calls include premium charges reflecting out-of-hours availability and immediate response capabilities. Weekend and bank holiday repairs command higher rates owing to the specialised nature of emergency technical services. Comprehensive cost estimates are provided before work commences, with clear explanations of recommended repairs and associated costs. Get a quote for your repair requirements.

Are your engineers qualified to work on all brands of industrial doors?

RID Repairs maintains a team of experienced engineers with extensive cross-manufacturer expertise developed through years of field experience and ongoing professional development. Our technicians regularly encounter diverse door systems and have developed comprehensive knowledge of various manufacturer specifications and repair requirements. Technical training encompasses both formal manufacturer programmes and hands-on experience with popular brands including Hörmann, Carteck, Novoferm, and numerous other industrial door manufacturers. This broad exposure enables our engineers to understand design principles and common failure patterns across different product lines. Diagnostic capabilities extend beyond brand-specific knowledge to fundamental mechanical and electrical principles. Springs, motors, control systems, and safety devices operate on similar principles regardless of manufacturer branding. Parts sourcing relationships with multiple suppliers ensure access to replacement components for most door systems. Compatible parts availability often provides cost-effective alternatives to original manufacturer components whilst maintaining performance standards. Older or discontinued door systems occasionally present unique challenges when manufacturer support is limited. Our engineers' broad experience often enables creative solutions utilising available components or system modifications that restore functionality whilst maintaining safety standards. Learn more about our team.